EcoPulse™ Advanced Fabric Filtration Systems

Low-cost of ownership process filtration

Available Features

• long bags elements

• Full-spectrum pressure cleaning (hi-med-low)

• On-line and off-line cleaning system

• Inlet designs for high dust applications

• Modular / field erected / explosion proof designs

Design Benefits

• Gas temperature up to 500°F

• Differential pressure up to 80 in. WG

• Long-bag technology saves space

• High-side inlet designs minimize can velocity

• Pre-chamber inlet eliminates abrasion

EcoPulse™ Advanced Fabric Filtration System

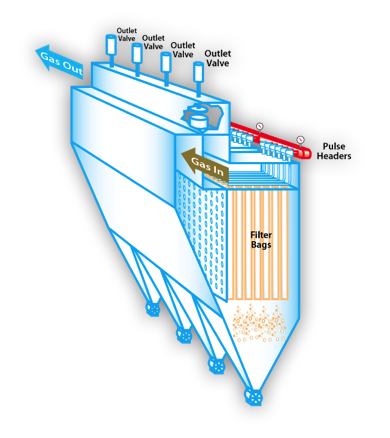

EcoPulse™ Arrangement without Inlet Valves

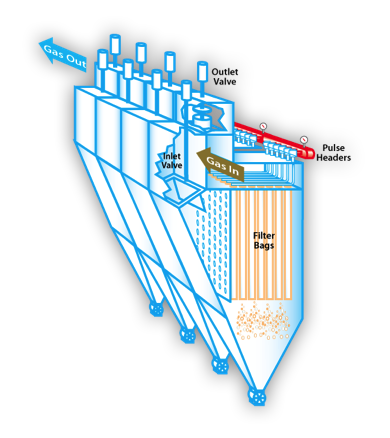

EcoPulse™ Arrangement with Inlet Valves

Two of Several EcoPulse™ Advanced Fabric Filtration System Arrangement Layouts

Dedusting Solutions

BoldEco Environment EcoPulse Series pulse jet fabric filters are ready to satisfy all the requirements of gas de-dusting with respect to reliability, low maintenance and spare parts standardization. According to the application and space available, various designs are available. Our extensive process experience and exclusive gas inlet design allows us to achieve the highest air to cloth ratio for any application while preserving filter maintainability and extending bag life.

EcoPulse filters are available for heavy duty applications in basic industries including cement, chemicals, steel, metals, incineration, power, etc.

EcoPulse Pulse-jet Fabric Filters

BoldEco offers the following fabric filter system solutions for dedusting applications:

EP-HP High-Pressure PulseJet Fabric Filters

The EcoPulse high-pressure PJFF design is implemented in applications with sticky or difficult to release dust and very high dust loads. EcoVent high-pressure PJFFs are the industry standard for bags below 6m (18 feet) in length. High-pressure PJFFs utilize pressures between 3-6 bar (45-90 psig).

EP-MP Med-Pressure PulseJet Fabric Filters

The EcoPulse medium-pressure PJFF design is implemented in applications with powdery or easy to release dust and medium to low dust loads. EcoVent medium-pressure PJFFs are the industry standard for bags greater than 6m (18 feet) in length. Medium-pressure PJFFs utilize pressures between 1-3 bar (15-45 psig).

EP-MH Hybrid-Pressure PulseJet Fabric Filters

With the addition of a VEnTo (Variable Energy-Timing Optimized) pulsejet controller, the any EcoVent PJFF can be converted to a hybrid-pressure design. The main advantage of a hybrid design is that the dust collector will automatically respond to changing dust collector conditions to provide the optimum pulsing pressure, thus resulting in a design that provides the best balance between performance and bag life. Hybrid-pressure PJFFs utilize pressures between 1-6 bar (15-90 psig).

Technical Expertise

Our technical department is specialized in the analysis, design and supply of custom engineered fabric filter retrofit technologies and in the supply, erection and commissioning of the new system, including performance guarantees.

Even the analysis of the gas moving system under the new operating parameters can be trusted to the competence of our fan specialists.

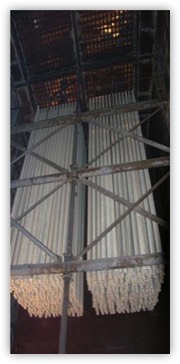

Filtering equipment can be selected with various bag lengths, typically from 4 to 10 meters (12 to 33 feet).

Bag Life Guarantee

Due to the unique experience of BoldEco Environment and with the implemenation of new technologies, such as the newly developed Vento Controller, CFD Technology and ePTFE membrane filter media, one can expect 5-6 years of bag life under normal use. With the installation of a Vento Controller BoldEco will DOUBLE a manufacturer's warranty on bag life. Ask us for details.

EcoVent™ Fabric Filter Accessories

BoldEco offers the following fabric filter add-on and retrofit solutions for dedusting applications:

VEnTO™ (PJFF Controller)

The VEnTo™ (Variable-Energy/Timing-Optimized) pulse-jet fabric filter controller is a microprocessor-based controller designed to control the main parameters of a pulse-jet fabric filter - Pulse Time, Pulse Duration, and Pulse Energy. By automatically controlling these main parameters, the fabric filter can be made to respond to any process condition, while at the same time conserve energy and extend bag life.

Tsunami™ (Reverse Fabric Filter Standing Shockwave Pulse Generator)

The Tsunami™ standing shockwave generator is a retrofit accessory designed to provide new life to existing reverse gas fabric filters. Greatly improved fabric filter performance can be gained by generating a programmable standing shockwave in the reverse gas cleaning duct, increasing the time between compartment isolation and cleaning cycles. This results in a more steady process control, increased bag life, reduced pressure drop, and decreased emissions.

View from Hopper of 26ft. Long Bag Dirty Side Gas Plenum

Full-immersion Pulse Valves on Long Bag System with

Vento (variable-energy/timing-optimized) Controller

EcoPulse™ ESP to Fabric Filter Conversions

EcoPulse Pulse-jet Conversion Packages

The latest emissions regulations have reduced the maximum allowable emission limits to such a degree that many existing precipitators cannot achieve compliance. In such cases, it becomes necessary to provide costly additional fields, or to install cost-effective, high efficiency, retrofit fabric filter technology in the existing casing.

Minimized Down Time

In many cases, the fabric filter portion of the retrofit can be assembled and tested on the ground. The ESP is removed in one piece and the new fabric filter section is lifted in one piece, reducing plant down time. In most cases the retrofit will require 1-2 weeks for the tie-in work.

A typical sequence is shown in our project gallery

Available ESP to FF Solutions

EP-MP Med-Pressure PulseJet Fabric Filters

The EcoVent medium-pressure PJFF design is implemented in applications with powdery or easy to release dust and medium to low dust loads. EcoVent medium-pressure PJFFs are the industry standard for bags greater than 6m (18 feet) in length. Medium-pressure PJFFs utilize pressures between 1-3 bar (15-45 psig).

EP-MH Hybrid-Pressure PulseJet Fabric Filters

With the addition of a VEnTo (Variable Energy-Timing Optimized) pulsejet controller, the any EcoVent PJFF can be converted to a hybrid-pressure design. The main advantage of a hybrid design is that the dust collector will automatically respond to changing dust collector conditions to provide the optimum pulsing pressure, thus resulting in a design that provides the best balance between performance and bag life. Hybrid-pressure PJFFs utilize pressures between 1-6 bar (15-90 psig).