OptiVap™ Advanced Atomizing Systems

Downflow

Evaporative Gas Cooling Tower

Applications: Cement, Lime, Incineration

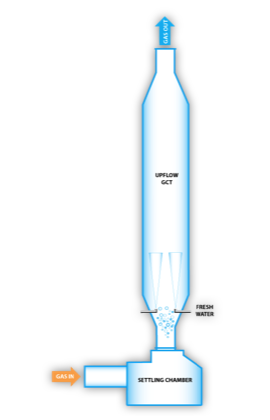

Upflow

Evaporative Gas Cooling Tower

Applications: Steel EAF, Steel BOF

Two of Several Gas Cooling Spray Chamber Arrangement Layouts

Industries

• Steel • Non-ferrous Metals Primary Process • Cement •

• Incineration • Boilers • Biomass • Waste-to-Energy •

EcoSprayTech Atomizing Technology Spectrum

Evaporative Gas Cooling Systems (EGC)

Gas Cooling Tower Applications

Spray cooling towers are used to cool and humidify hot gases in order to improve the efficiency of the dust collector or to allow the use of lower priced filter media. Spray cooling towers are also used to condense out that fraction of the gases, trapping that portion that would otherwise penetrate the dust collector, resulting in a significant reduction in trace emissions.

STM EcoSystems implements low maintenance dual fluid air+water injection systems to drastically shorten the evaporation time, resulting in dry bottom operation.

A sophisticated water regulation system coupled with rapid temperature sensors provides a quick response to temperature variations to achieve precise tower outlet gas temperatures.

Detailed analyses, including model studies and computer simulations of gas distribution and tower geometries are carried out to prevent gas turbulence or poor gas / water interaction.

In-duct Humidification Applications

In the absence of a properly designed spray cooling tower, due to the optimum performance of the OptiVap spray nozzle, we can utilize the existing ducting as a spray cooling chamber. Cooling and adding humidity to the hot gases decreases the resistivity of the dust particles and reduces the gas volume, improving the efficiency of the ESP dust collector.

STM EcoSystems offers the following gas cooling solutions for air pollution control applications:

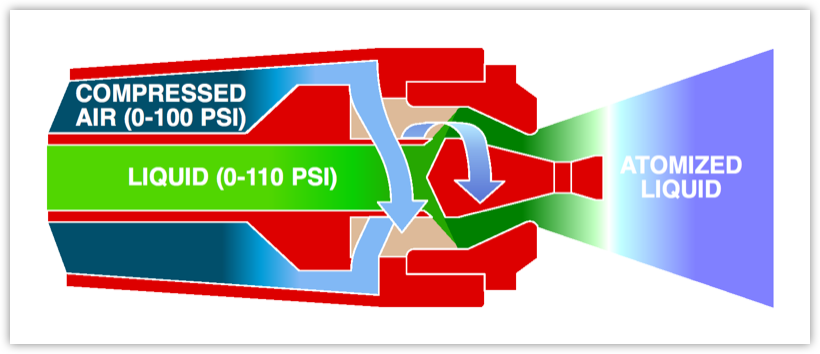

Dual Fluid Spray Systems

The EcoSprayTech dual-fluid evaporative gas cooling system utilizes a newly developed dual-fluid (air atomized) nozzle technology that uses less than 5.5 CFM or air per GPM (2.5 m3/h of air per LPM) of water injected. For the same droplet size generation, the closest competitive system utilizes more than 7.0 CFM or air per GPM (3.2 m3/h of air per LPM) of water injected. That makes our nozzle 30% more efficient than its nearest competitor!

Advantages of the EcoSprayTech System:

• 30% less compressed air consumption

• Able to operate at air deficit without droplet size degradation

• Single or multiple nozzle spray lances

• CFD designed spray cooling chambers

• Low-cost point-of-use compressor systems

• No need for water tanks

The EcoSprayTech Atomizer

Spray Cooling Lances on Steel EAF

In-duct Chemical Injection Spray Lances For Coal Fired Power Plant Application

Upflow Spray Cooling Tower on Steel EAF

Down flow Spray Cooling Tower in SS

STM EcoSystems - 83 Princeton Ave. Unit 3D - Hopewell - NJ - USA - 609.644.3797