EcoCer™ Advanced Catalytic Systems

Low-cost Selective Catalytic Reduction (SCR) Combined with High Temperature (HT) process filtration

Available Features

• 10-foot long ceramic candle elements

• On-line or off-line cleaning system

• Formulations available to avoid ABS formation

• Designed for high dust applications

• Full-spectrum pulse pressure cleaning

• Modular casing designs

• Explosion resistant designs available

Design Benefits

• DeNOx and PM removal in single unit

• Formulation for high temperature (≥650°F)

• Formulation for low temperature (≤300°F)

• Low operating differential pressure

• Filtration aspect extends lifetime of catalyst

• Low-cost soot-blowing system

• Lowest operating and maintenance cost

EcoCer™ Advanced Catalytic/Filtration System

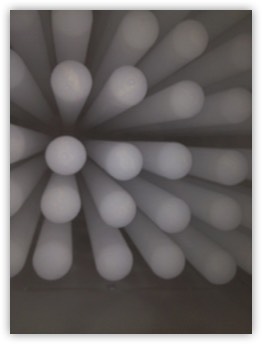

EcoCer™ Filtration Elements are the heart of the catalytic filtration system (DeNOx and PM)

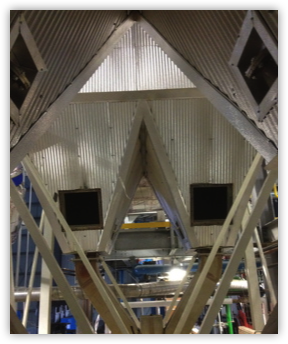

BoldEco Environment EcoCer™ Series Selective Catalytic Reduction (SCR) combined with high temperature filtration are the ultimate in NOx and PM2.5 removal. pulse jet fabric filters are ready to satisfy all the requirements of gas de-dusting with respect to reliability, low maintenance and spare parts standardization. According to the application and space available, various designs are available. Our extensive process experience and exclusive gas inlet design allows us to achieve the highest air to cloth ratio for any application while preserving filter maintainability and extending bag life.

Our EcoCer™ system utilizes ceramic catalytic elements impregnated with Haldor Topsoe catalysts, with whom one of our BoldEco Group companies has a development and cooperation agreement for various applications, including SCR DeNOx, diesel engine soot catalysis and filtration, and marine seawater scrubbing pre-filtration. These elements offer excellent surface filtering performance with very fine particulate, such as diesel particulate. In fact, diesel motors emit very fine aerosols (0.05-1.0 μm) composed of unburned organics (soot) and slightly larger inert ashes.

EcoCer™ system separate particulate from the gas stream as follows :

• within the matrix of the ceramic where it is oxidized at high temperature (≥650°F) by the action of the catalyst-impregnated substrate,

• on the external surface of the ceramic matrix (surface filtration) where it is oxidized at high temperature (≥650°F) combined with a soot blowing system (engine off-line), or through the injection of an oxidizing agent (engine on-line / back-up). The latter removal option is selected according to the engine type and the fuel utilized.